This Speaking in Code article is a tribute to concrete special inspectors everywhere for what they do daily. To appreciate the magnitude of the concrete special inspector’s duties, let’s begin with the International Building Code (IBC) definition of “special inspection” found in Chapter Two of the IBC code book.

“Special Inspection. Inspection of construction requiring the expertise of an approved special inspector in order to ensure compliance with this code and the approved construction documents.”

Based on the definition of special inspection by the IBC code, we understand that the concrete special inspector is responsible for observing, inspecting, and testing the various concrete construction methods and materials in order to monitor compliance with the building code and the construction documents.

The various types of concrete tests and special inspections required by the general building code result from numerous model codes and standards in addition to the IBC code. The primary codes and standards are as follows:

- International Building Code (IBC)

- Structural Concrete Building Code (ACI 318)

- Specifications for Structural Concrete (ACI 301)

- American Society for Testing and Materials (ASTM)

- Project Approved Construction Documents

Of the five codes and standards above, the two that invoke the most concrete special inspections and tests on project work are ACI 301 and ACI 318. ACI 301 and ACI 318 are written in mandatory language and create the lion’s share of the project concrete special inspector’s code-required inspection and testing duties. ACI 318 (the code) presents minimum requirements for construction methods and materials relative to public safety. ACI 301 presents more than the minimum requirements on construction methods and materials relative to the actual concrete construction. ACI 318 strives to guarantee a safe design, emphasizing public safety, while ACI 301 is about good construction practices.

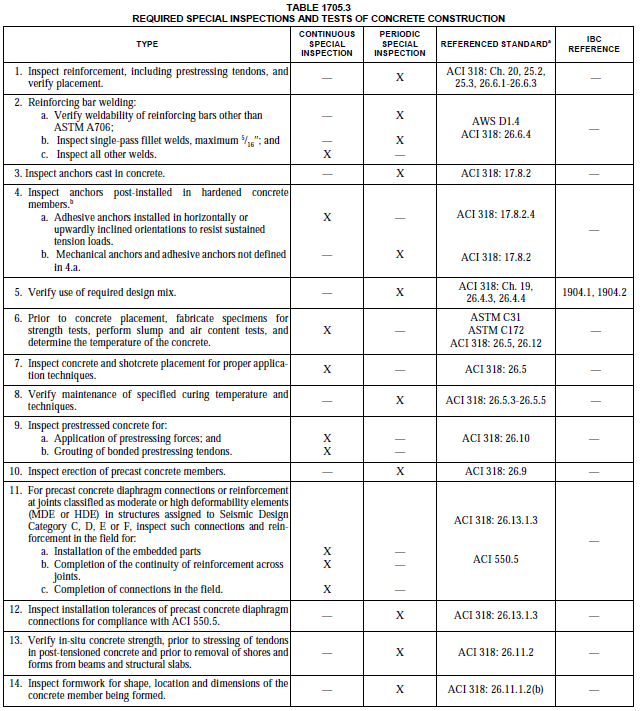

Now, back to all those duties for which the concrete special inspector is responsible. What most people in the design and construction community think of when they think of the project concrete special inspector is those specific inspections and tests performed on ready-mixed concrete when it is delivered to the job site in its plastic state. These tests include slump tests, air content tests, unit weight tests, concrete temperature tests, and molding compressive strength test specimens at the project site. While these particular specialized tests and inspections are provided by the concrete special inspector as required by the code, and specifically by Table 1705.3 in Chapter 17 of the IBC code, they provide much more!

Table 1705.3 lists fourteen different categories of special inspections in the inspection type column; however, it would be wrong to assume that Table 1705 stipulates only fourteen types of special inspections. Suppose you review the different code sections (mainly ACI 318 code sections) cited under the “reference standard column” of Table 1705.3. In that case, you will discover that the concrete special inspector is responsible for more than 50 inspections and tests according to applicable reference standards in Table 1705.3.

Listed herewith are a few (but not all) of those inspections and tests for which the concrete special inspector is charged in the various reference standards cited in IBC Table 1705.3:

- Verifying that the concrete reinforcing steel installation and spacing comply with the contract documents, ACI 301, ACI 318, and the Concrete Reinforcing Steel Institute (CRSI)

- Verify that concrete forms comply dimensionally with contract documents

- Monitor concrete cover tolerances in accordance with ACI 301, Section 3, and ACI 117

- Observe the installation of concrete anchor rods for compliance with the code

- Observe and report diameter, grade, type, and length of anchor rod or embedded item

- Verify that the concrete delivered to the job site complies with the approved mix design

- Verify that concrete complies with proper exposure class according to ACI 318, Chapter 19

- Observe ready-mix truck delivery tickets for compliance with ASTM C 94

- Observe mixing, unloading, and addition of water to the truck in accordance with ASTM C 94

- Verify that concrete truck mixing time complies with parameters of C 94 and ACI 301

- Observe concrete placement compliance according to ACI 318, Section 26.5, including hot weather and cold weather concrete placement requirements

- Observe that debris, standing water, and ice are removed from spaces to be occupied by concrete before placement

- Observe that the concrete is transported from the ready-mix truck to the job site location in accordance with contract documents, ACI 318, and ACI 301

- Concrete elements of the project should be maintained at a temperature of at least 50 F and in a moist condition for the first seven days after placement (ACI 318, Section 26.5.3.2)

- Perform plastic concrete quality control tests according to ACI 301, ACI 318, and IBC

- Provide initial curing for concrete test specimens (including max/min thermometers) according to ASTM C 31 and IBC Table 1705.3

- Observe and report concrete temperatures and ambient air temperatures according to contract documents and ACI 301

- Denote accurate location within the concrete placement represented by the QC sample and compressive test specimens molded in the field

- Verify that the adhesive anchor installer is a certified installer according to ACI 318, Section 26.7.1

- Provide adhesive anchor special inspections in accordance with ACI 318 and ACI 355.4

- Observe concrete finishing operations for compliance with ACI 301 and ACI 318

- Observe construction joints, isolation joints, etc., for compliance with contract documents and ACI 301

- Observe concrete curing and protection according to ACI 318 and ACI 301

- Report discrepancies to the contractor, building official, and registered design professional (in responsible charge) on the same day

- Observe curing and protection of concrete after placement according to ACI 301, ACI 318, and contract documents

While the concrete inspection and tests stipulated in this particular article are some of the primary ones provided by the concrete special inspector on typical project work, many others are not listed. It would be impossible to list every concrete special inspection and test set forth in all the applicable building codes and standards denoted in Chapter 35 (Referenced Standards) of the IBC code. One very important standard that influences concrete special inspections that has not been addressed (to any extent) is ACI 355.4, entitled “Qualification of Post-Installed Anchors in Concrete.” ACI 355.4 is the major source of the required special inspections related to adhesive anchors. Section 13 of ACI 355.4 literally itemizes code-required special inspections, which ones are periodic inspections, and which ones are continuous inspections.

Does every concrete special inspection and test in every applicable code and standard get provided by the concrete special inspector on all concrete elements? No – not ever! That would be perfection and (overall) perfection is rare on construction projects. The design drawings aren’t perfect, the shop drawings aren’t perfect, the statement of special inspections aren’t perfect, the contractor and various trade people aren’t perfect, and the special inspector is not perfect, either. However, if the project team is really in sync with one another, all major discrepancies will be discovered and resolved during the construction phases.

Remember — while some of the concrete special inspector’s duties are continuous, most are periodic according to code, which means that the concrete special inspector will observe many of the construction methods and materials on a random basis. Regardless, I tip my hat to the guys and gals who show up on the project every day and endeavor to ensure everything is built to code and the structural elements will function as designed.