Many geographic areas in the United States are subject to unpredictable weather. Masonry under construction needs to be protected from detrimental moisture intrusion and other weather elements, particularly when there is a possibility of freezing temperatures.

Successful cold-weather masonry construction requires knowledge of code requirements, workforce, planning capabilities, and the capacity to be flexible and innovative. Building codes mandate certain procedures when constructing masonry during cold weather when the ambient temperature is below 40 F. The requirements (compliance criteria) are grouped within temperature ranges. While the provisions are prescriptive, there is considerable latitude for the contractor to use individual methods to satisfy the code requirements. This is in recognition of the wide variety of possible winter construction site conditions and the fact that materials, equipment, and methods of construction technology advance rapidly.

Understanding Temperatures

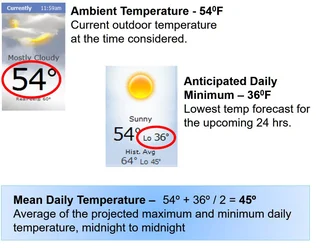

Understanding temperature terminology and ranges is critical to applying the appropriate code-mandated provisions for cold-weather masonry. Mandatory temperature ranges are required for cold-weather masonry construction and cold-weather masonry protection periods. There is a clear distinction between construction and post-construction (protection) requirements for cold-weather masonry work.

- Construction-phase temperature ranges are based on the ambient temperature, which is the temperature at the job site during masonry installation.

- Post-construction protection requirements for grouted masonry are based on the anticipated daily minimum temperature, which is the forecast low for the upcoming 24- or 48-hour period (depending on the type of cement used in the grout).

- Post-construction protection requirements for ungrouted masonry are based on the anticipated mean daily temperature, which is the forecasted average temperature for the upcoming 24-hour period.

So, what exactly is cold weather insofar as masonry construction is concerned? The masonry code (TMS 602, Article 1.8C) states that when the ambient air temperature is below 40F, you must implement cold weather procedures stipulated in 1.8C. The provisions of Article 1.8C are mandatory. Cold weather for masonry, then, is whenever the average temperature around the masonry is below 40 F.

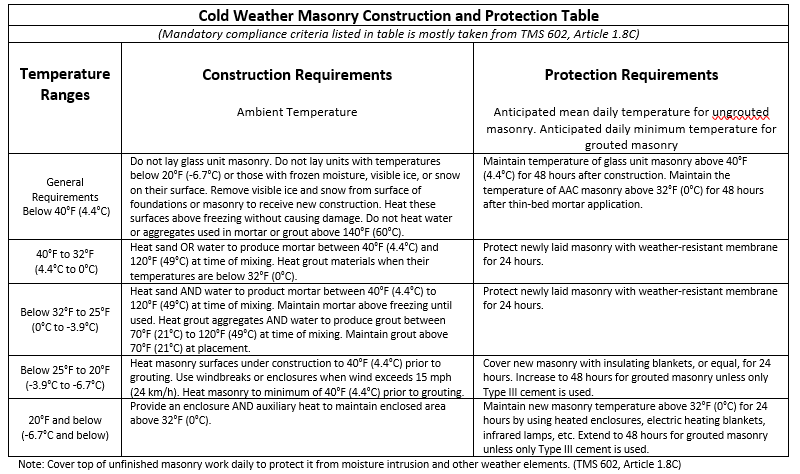

The “Cold-Weather Masonry Construction and Protection Table” depicted above lists code-mandated construction requirements and masonry protection requirements at specific temperature ranges during cold-weather masonry work. The code compliance criteria presented in this table are derived from three pages of varied criteria specified in TMS 602, Article 1.8C. Reviewing the data in a tabular format is a little easier to understand; it is not as overwhelming as reviewing the data in the narrative format presented in the TMS 602 code book.

Miscellaneous Cold-Weather Masonry Special Inspection Items

- Protect materials from contaminants (pallets) so they are not wetted by rain, snow, or groundwater.

- Do not lay masonry units with either a temperature below 20 F or frozen moisture, visible ice, or snow on their surface.

- Remove visible ice and snow from the top surface of existing foundations and masonry to receive new construction. Heat these surfaces above freezing using methods that do not result in damage.

- Cover the top of unfinished masonry to protect it from moisture intrusion; in colder weather, this cover may need to be insulated blankets.

- The minimum temperature of mortar should be 40 F.

- The minimum temperature of masonry grout should be 70 F.

- Remove visible ice from any material before it is used in masonry installation.

- Heat grout materials when the temperature of the materials is below 32 F.

- Heat sand or mixing water to produce mortar with a minimum temperature of 40 F.

- Heat masonry surfaces under construction to a minimum of 40 F when required by the masonry code.

- Use insulating blankets and heated enclosures when required by the code.

- Protect newly constructed masonry by covering it with a weather-restrictive membrane for 24 hours after being completed.

Hydration and strength development in mortar usually occurs at temperatures above 40 F. If the mortar used during construction is below this temperature, it may not set properly, and if water is retained in the joint, frost damage may result. Mortar will typically cure to about 60% of its final cure strength within the first 24 hours. It will, generally, require about 28 days to reach its final 28-day design strength (provided proper protection of masonry is provided).

There are many things that the mason can do during masonry construction (in cold weather) to enhance mortar workability and quality. During cold weather, masons may string shorter mortar beds to limit exposure to cold temperatures by the cold mortar. Mortar takes longer to set in the cold, so masons may need to wait to lay up the next course, and before tooling joints. The age-old “tooling when thumbprint hard” is as applicable in cold weather as in average weather. Mortar is thumbprint-hard when the image of your thumbprint can be left in the mortar. When the mortar is too wet, it will not form a thumbprint; it just sticks to the thumb. Mortar must be relatively stiff to be classified as thumbprint hard. In this state, the mortar compacts easily and provides proper compression against the masonry unit. A properly tooled joint is necessary to obtain a weatherproof mortar joint.