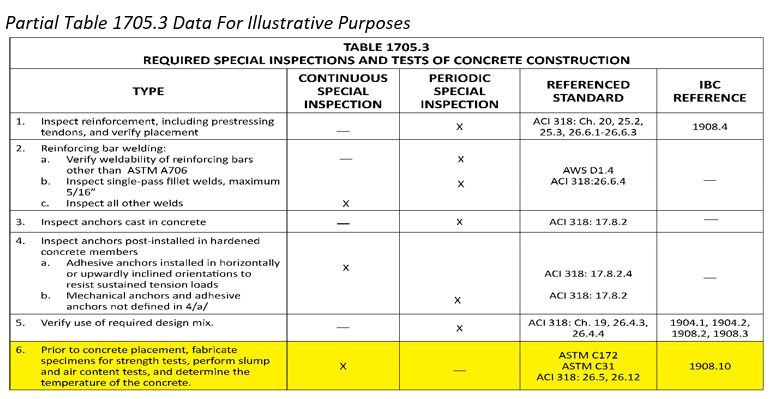

Anyone involved with concrete special inspections should be familiar with Table 1705.3, “Required Special Inspections/Tests of Concrete Construction.” Concrete special inspectors, construction managers, and project engineers should also become acquainted with the two reference columns at the far right-hand side of Table 1705.3

Does Table 1705.3 list all required inspections and tests the project special inspector must provide? Hardly! The table lists some minimum IBC code-required special inspections that the project special inspector must provide. Additional code compliance criteria, inspections, and tests are specified by ACI 318 (concrete code), IBC Chapter 19 (concrete), and ACI 301, “Specifications for Structural Concrete.”

There is a singular distinction between Table 1705.3 and IBC Chapter 19-required special inspections; the IBC code establishes the minimum requirements to provide a reasonable level of safety regarding the inspection and testing of construction materials and construction methods. Construction documents are allowed to require more inspections and testing than the IBC code. When the construction documents require fewer inspections and less testing than the IBC code, the minimum requirements of the IBC code are invoked.

The sole purpose of this Speaking in Code article is to discuss and explain the importance of the two reference standard columns of Table 1705.3. One column is labeled “Referenced Standard” and the other labeled “IBC Reference.” The “Referenced Standard” column lists various ACI, AWS, and ASTM standards that apply to the inspection type listed in the first column. The “IBC Reference” column lists different sections of IBC Chapter 19 applicable to the inspection type listed in the first column of the table.

It is important to remember that IBC Chapter 19 is just as much a part of the building code as IBC Chapter 17 and Table 1705.3. Chapter 19 largely duplicates code verbiage specified in ACI 318; however, Chapter 19 also contains code-required inspections, tests, and compliance criteria not addressed in ACI 318 or Table 1705.3. An excellent example is Chapter 19, Section 1904.2, which addresses nonstructural concrete. This section stipulates specific minimum compressive strengths and target air content percentages for all nonstructural concrete F classes (exposure classes). ACI 318 (concrete code) does NOT list any durability requirements (compressive strength or air content) for nonstructural concrete.

The IBC Chapter 19 limits for strength and air content are not exceptions to ACI 318 but rather a distinct set of code requirements. You would never know this nonstructural concrete code compliance criteria existed if you did not track across Table 1705.3 to the right and review the information under the “IBC Reference” heading, specifically IBC Chapter 19, Section 1904.2.

Let’s explore the importance of the “Referenced Standard” and “IBC Reference” columns of the table above. Focus on line item six under the first column. It is easy to surmise from the information that line item six primarily addresses the plastic concrete tests provided by the project special inspector, like molding concrete test specimens, slump tests, air content tests, concrete temperature tests, etc. However, as you track to the right across the table to the information under “Referenced Standard,” you will see some ASTM standards listed, as well as a couple of sections of ACI 318 (concrete code).

The ASTM standards tell the reader how to properly sample fresh concrete and mold the concrete compressive strength specimens in the field. The ACI 318 sections cited in line item six are Sections 26.5 and 26.12. Section 26.5 is roughly six pages with 3,000 words of code-speak regarding concrete production and construction code compliance criteria. It includes code compliance requirements for concrete production, concrete placement, concrete curing, concrete design information, cold weather concreting criteria, and more. Section 26.12 of ACI 318 includes code compliance criteria related to concrete evaluation and acceptance, testing frequency, acceptance criteria for concrete compressive strength specimens, requirements for investigating low-strength test results, compliance criteria for testing concrete test core samples, etc. These two ACI 318 sections comprise more than 5,000 words of code compliance criteria that concrete special inspectors may never know if they don’t review the stipulations of the “Referenced Standard” column.

If the reader does not review the “Referenced Standard” column, they could think that the only special inspections required are the plastic concrete tests cited in the first column. This thinking needs to be corrected. Since “X” is denoted under the continuous special inspection column (column two) of line item six, we know that continuous full-time special inspections are required while fresh plastic concrete is placed on the project.

As you review the information in the “IBC Reference” column on line item six, note that Section 1908.10 of IBC Chapter 19 is listed. Section 1908.10 addresses compliance criteria for shotcrete and is only applicable to shotcrete and not ready-mixed concrete; therefore, Section 1908.10 is not a factor. Shotcrete is the commonly accepted and generic name for pneumatically projected mortar or concrete.

Let’s take a moment and summarize the importance of the “Referenced Standard” and “IBC Reference” columns of Table 1705.3. If the special inspector does not apply the compliance criteria stipulated in these two columns, more than 50% of the applicable compliance criteria will never be applied to the project concrete. A special inspector applying only the criteria specified under column one will provide the appropriate inspection and tests set forth regarding molding concrete test specimens for strength tests, slump tests, air content tests, and concrete temperature information. However, it is problematic if the information outlined in the two reference standard columns is ignored or unknown; code compliance criteria regarding sampling concrete, concrete placement criteria, concrete production requirements, segregation/cold joint criteria, concrete curing criteria, cold weather concrete criteria, construction joint criteria, and additional code-required criteria may never be applied to the project concrete.

The six pages of code-required compliance criteria specified in the two reference columns also invokes ASTM C 94, “Standard Specification for Ready-Mixed Concrete,” which is the backbone of code-required compliance criteria for all project ready-mixed concrete. ASTM C 94 is also invoked by IBC Chapter 19.

The lesson learned here is simple but important: Always review and become familiar with the code compliance criteria in the reference standard sections of Table 1705.3 when providing special inspections on project concrete.