If you have questions regarding the minimum special inspection requirements for load-bearing or engineered masonry construction, you will find most of your answers in Table 4 of the TMS 402/602 masonry code. There is some uncertainty regarding interpretation of the numerous masonry special inspection tasks listed in Table 4. This uncertainty is understandable, because Table 4 is relatively new to the masonry code world; this table never existed in previous masonry code editions before the publication of TMS 402/602-16.

Let’s start with simply understanding the meaning of the masonry code acronym TMS 402/602, which is not as simple as one may think at first blush. TMS is the acronym for The Masonry Society, which describes itself as “the premier professional, technical, and educational society dedicated to the advancement in knowledge of masonry technology.” Understanding the 402/602 part of this annotation is essential as well. 402 is the TMS 402/602 code book’s code part comprising about 254 pages. 602 is the specifications part of the TMS 402/602 code book, which includes an additional 90 pages. The 402 code and the 602 specifications are combined into one TMS 402/602 code book.

TMS 402 (the code) is written like the International Building Code (IBC) in chapters and sections, while TMS 602 (the specifications) is written like a CSI specification in parts and articles. TMS 402 adopts TMS 602 as a reference standard; therefore, all the masonry compliance criteria specified in TMS 602 are adopted by TMS 402 in its entirety.

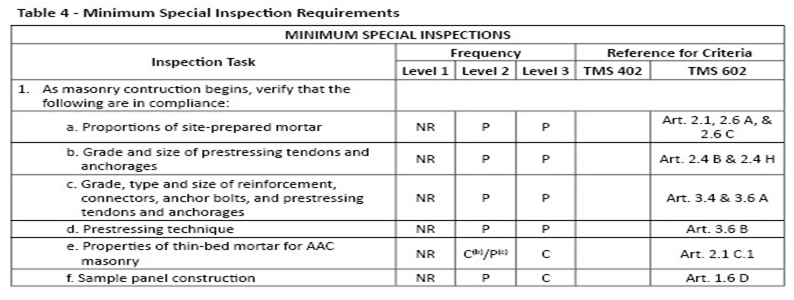

The purpose of TMS 602 Table 4 is to list the minimum special inspection requirements of the code, and it works well. Let’s look at the different sections of Table 4 of TMS 602. Note that the title of Table 4 is “Minimum Special Inspections Requirements,” and this verbiage in the table’s title is important. The code-required compliance criteria specified in Table 4 are the minimum code requirements for any masonry project comprised of load-bearing or engineered masonry. The contract documents can require MORE compliance criteria than the minimum requirements of Table 4. Still, the special inspections cited in Table 4 always represent the minimum threshold requirements for project special inspections and testing.

Table 4 offers three levels of special inspections. Level 1 special inspections generally apply to empirically designed masonry, brick veneer, etc., as referenced in Appendix A of TMS 402. Level 2 special inspections generally apply to masonry described in Part 3, Appendices B and C, and non-essential Risk Categories II and III, according to IBC Table 1604.5. Level 3 special inspections are required for masonry construction in structures assigned a Risk Category IV by IBC Table 1604.5 and identified as essential structures.

Let’s discuss the anatomy of TMS 602 Table 4 and see how it works.

The partial Table 4 above lists the various special inspection tasks assigned to the number 1a special inspection task of Table 4 and are listed in column 1 of the table. The following three columns of the table list the level of special inspections and the frequency of the inspections. An “NR” means not required, “P” means periodic inspections, and “C” means continuous inspections. The levels of special inspections, according to Table 4, are Levels 1, 2, and 3. The levels of special inspections were discussed briefly earlier in this article, but more extensive commentary on the levels of masonry special inspections can be found in Section 3.1 of the TMS 402 code.

The two far right-hand columns are code compliance criteria stipulated by TMS 402 and TMS 602. You will note that the first inspection task – proportions of site-prepared mortar – invokes Articles 2.1, 2.6A, and 2.6C of TMS 602. Article 2.1 requires that the project masonry mortar complies with ASTM C270, “Standard Specification for Mortar for Unit Masonry.” Article 2.6A stipulates mortar mixing times (3 to 5 minutes) and requires that mortar not used within 2 ½ hours be discarded. Article 2.6C is compliance criteria for thin-bed mortar for Autoclaved Aerated Concrete (AAC) masonry and is not applicable for regular ASTM C90 masonry mortars.

Inspection task 1c addresses masonry joint reinforcement and prestressing tendons. Table 4 denotes that the frequency of these inspections are periodic and cites Article 3.4 and 3.6A as the primary sources for code compliance criteria. Article 3.4 lists many compliance criteria ranging from the minimum cover of the reinforcing placement of the joint reinforcement, splices, wall ties, and anchor bolts. The main point here is that the special inspector must review the reference criteria cited in the TMS 402 and TMS 602 columns of Table 4 to recognize the magnitude of special inspections that must be provided.

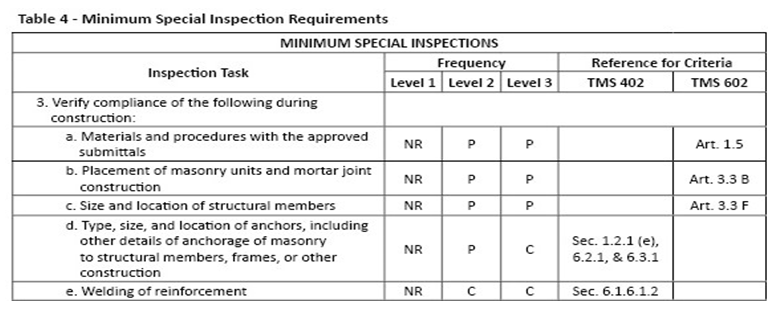

In the above portion of Table 4, inspection task 3 stipulates that the masonry special inspector verifies compliance with numerous aspects of the masonry construction. Inspection task 3a instructs the special inspector to review approved submittals (certificates of compliance) for compliance with the code and cites Article 1.5 of TMS 602. Article 1.5 invokes mortar compliance with ASTM C270 and grout compliance with ASTM C476, “Specification for Grout for Masonry,” and material certificate submittals compliance with the code. These material submittals include reinforcement, anchors, ties, fasteners, masonry units, and even cold and hot weather construction procedures.

Article 1.5 also addresses the qualifications of the laboratory and field personnel. Inspection task 3b specifies compliance criteria related to the placement of the masonry units and mortar joint construction and cites Article 3.3B of TMS 602. Article 3.3B lists varied compliance criteria for laying the concrete masonry units (CMUs) and mortar joint construction at the project site.

To summarize, the masonry special inspector should review and be familiar with all the reference criteria specified in the TMS 402 and TMS 602 columns of Table 4. Table 4 includes only about twenty special inspection tasks at first glance; however, invoking all the reference criteria in the TMS 402 and TMS 602 columns increases those special inspection responsibilities to over 100+ different tasks. These inspections and tests are the MINIMUM special inspections required on the project.