Reference Standards cited in this article:

International Building Code (IBC)

Building Code Requirements for Structural Concrete (ACI 318)

Specifications for Structural Concrete (ACI 301)

Standard Practice for Selecting Proportions for Concrete (ACI 211.1)

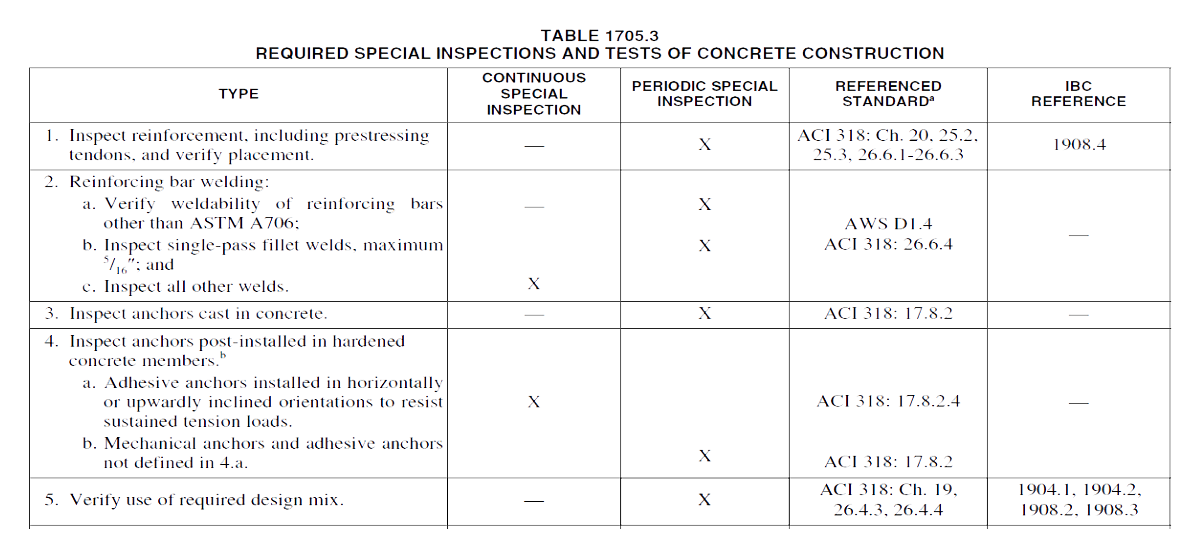

Every construction project in the country uses at least one concrete class during construction phases, and most will include several. All project concrete is subject to special inspections on many levels, but the code compliance criterion that raises the most questions and debates is special inspection Type 5 in Chapter 17, Table 1705.3, of the IBC code. This line item requires that the special inspection agency “Verify use of required design mix,” and the table notes that this special inspection be periodic during project construction.

What does this mean? Does it imply that the project special inspector must verify that the concrete truck delivery ticket reflects a concrete mix ID number corresponding to an approved concrete mix for the project? Or does this line item in Table 1705.3 require more input from the special inspection agency? Alas, the code demands more than just the review of the concrete delivery ticket by the special inspector. Please read on to see why this is true.

When you review the referenced standard column of Table 1705.3 as it pertains to Type 5, you will see that the referenced compliance criteria include all of Chapter 19 of the concrete code (ACI 318) as well as Sections 26.4.3 and 26.4.4 of ACI 318. It is important to note that the compliance criteria stipulated in the referenced standard column define the magnitude of the special inspections required. Section 26.4.3 of ACI 318 addresses code compliance criteria, and it states that “Concrete mixture proportions shall be established in accordance with Article 4.2.3 of ACI 301 or by an alternative method acceptable to the licensed design professional.” If Article 4.2.3 of ACI 301 is used, the strength test records for establishing and documenting concrete mixture proportions shall not be more than 24 months old.

There are two different methods offered by ACI 301, Article 4.2.3, for selecting concrete mix design proportions and complying with the code:

- Sample standard deviation using field test data and records representing materials, quality- control procedures, and climatic conditions similar to those expected in the This method uses statistical analysis to select the required average strength for the project concrete. There are many ACI 301 criteria and rules associated with the statistical analysis used to develop mix designs per the sample standard deviation method. The compressive strength tests must be consecutive and represent the same mixture proportions (and materials) as proposed for the project concrete mixture, including air content and slump ranges.

- Trial mixtures where project mix proportions are based on at least three trial mixtures following the compliance criteria stated in ACI 301, Article 4.2.3.4b. The materials used in the trial mixtures should be the same materials and proportions used in the proposed project concrete. The trial mix proportions must produce a range of compressive strengths encompassing the specified design strength of the project concrete mixture.

All project concrete mix designs must be developed using one of the methods specified by Article 4.2.3 of ACI 301. The mix designs and material proportions must comply with all ACI 301 and ACI 318 compliance criteria, including the standards required by ACI 318, Chapter 19, “Concrete Design and Durability Requirements.” The mix designs proposed for project work must comply with concrete exposure class criteria as required in Table 19.3.2.1 and other Chapter 19 tables. It should be reiterated that the code allows the concrete mix design to be accepted by a licensed design professional even if the mixture does not comply with code criteria. This type of mix design should also be submitted to the Registered Design Professional (RDP) in Responsible Charge for specific project approval and to the Authority Having Jurisdiction (AHJ).

Regardless of which of the two ACI 301 methods are used to develop the proposed project concrete mix designs, the mix proportions must comply with the applicable code compliance criteria of ACI 318 and ACI 301 in the areas of cement factors, maximum water-cement ratios, minimum compressive strengths, air content, exposure class, percent of fly ash, etc. The project concrete mixes must also be developed and proportioned to comply with the requirements of the construction documents. The mix proportions are generally selected per ACI 211.1 methods to provide a first approximation of concrete proportions intended to be checked by trial batches in the laboratory or field and adjusted, as necessary, to provide the desired characteristics of the concrete.

A good material proportion “rule of thumb” regarding concrete mixtures is the 10:20:30:40 mixture ratio which is about 10% cement, 20% air and water, 30% sand, and 40% stone based on the absolute volume of the concrete mixture. Of course adjustments will have to be made from this mixture to develop project-specific concrete mixtures; the mixture must handle concrete workability requirements based on concrete placement configurations, reinforcing steel schemes, fineness modulus of the fine aggregate, and the size of coarse aggregate, etc.

Let’s once again address the critical special inspection question posed in the first paragraph of this article.

Question: Does “verifying the use of the required mix design” (Table 1705.3) mean the project special inspector verifies that the concrete truck delivery ticket reflects a concrete mix ID number corresponding to an approved concrete mix?

Answer: Yes. The special inspector should review the concrete delivery ticket to confirm that the concrete delivered to the project site is an approved concrete mixture based on the concrete class ID number. However, the code does require MORE from the special inspection agency than a review of the concrete delivery tickets.

The code (ACI 318) requires that the RDP assign exposure classes based on the severity of anticipated exposure of project concrete elements for each exposure category in Table 19.3.1.1. Each concrete mix design approved for use on the project should be assigned a mix ID number that conveys the exposure class of the concrete, and this mix ID number should be noted on each project concrete delivery ticket. The project special inspector and the contractor should review each concrete delivery ticket to confirm the exposure class and code compliance.

The code requires that the concrete delivery ticket denote pertinent information, such as the proportions of materials and the information needed for the special inspector to calculate the total mix water in the mixture. Total mix water includes free moisture on aggregates, batch water, wash water in the mixing drum, and water added by the truck operator. The ticket should also reflect any water contributed as ice at the plant during hot weather concreting. Much of the information required by the code and the construction documents regarding the concrete reports depends upon the concrete delivery ticket data being complete.

All approved concrete mix designs (including all statistical data used to establish required average strength) should be copied and provided to the special inspection agency before the commencement of project concrete construction phases so they can review the mix designs for code compliance. The special inspection agency should also receive the appropriate mix design ID numbers of all approved project concrete mixtures.