Concrete Exposure Classes & Code Compliance Criteria

How does a person know which particular exposure class of concrete to use on each of the different types of concrete elements in the project? The simple answer is for Speaking in Code (SIC) to tell the person to spend some time reading ACI 318, Chapter 19, Section 19.3, “Concrete Durability Requirements.” It’s a big section – about eight pages – and it is loaded with ACI 318 code compliance verbiage about exposure categories and classes of concrete.

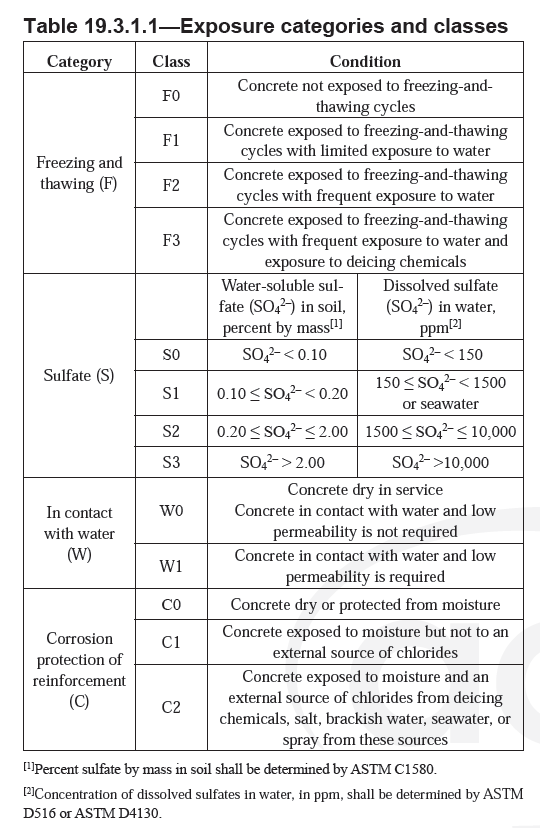

Concrete code criteria for concrete exposure classes hasn’t been around all that long. The concrete code (ACI 318) adopted the exposure categories and classes with the 2008 version of the code. The ACI 318-14 version of the concrete code lists four exposure categories that affect the requirements for concrete to ensure adequate durability in Table 19.3.1.1.

Exposure Category F applies to exterior concrete that is exposed to moisture and cycles of freezing and thawing with or without deicing chemicals.

Exposure Category S applies to concrete in contact with soil or water containing deleterious amounts of water-soluble sulphate ions.

Exposure Category W applies to concrete in contact with water, but not exposed to freezing and thawing, chlorides, or sulphates.

Exposure Category C applies to non-prestressed and prestressed concrete exposed to conditions that require additional protection against corrosion of reinforcement. Severity of exposure within each category is defined by classes of concrete. Increasing number values represent increasingly severe exposure conditions. A classification of 0 is assigned if the exposure severity has negligible effect (is benign) or the exposure category does not apply to the member.

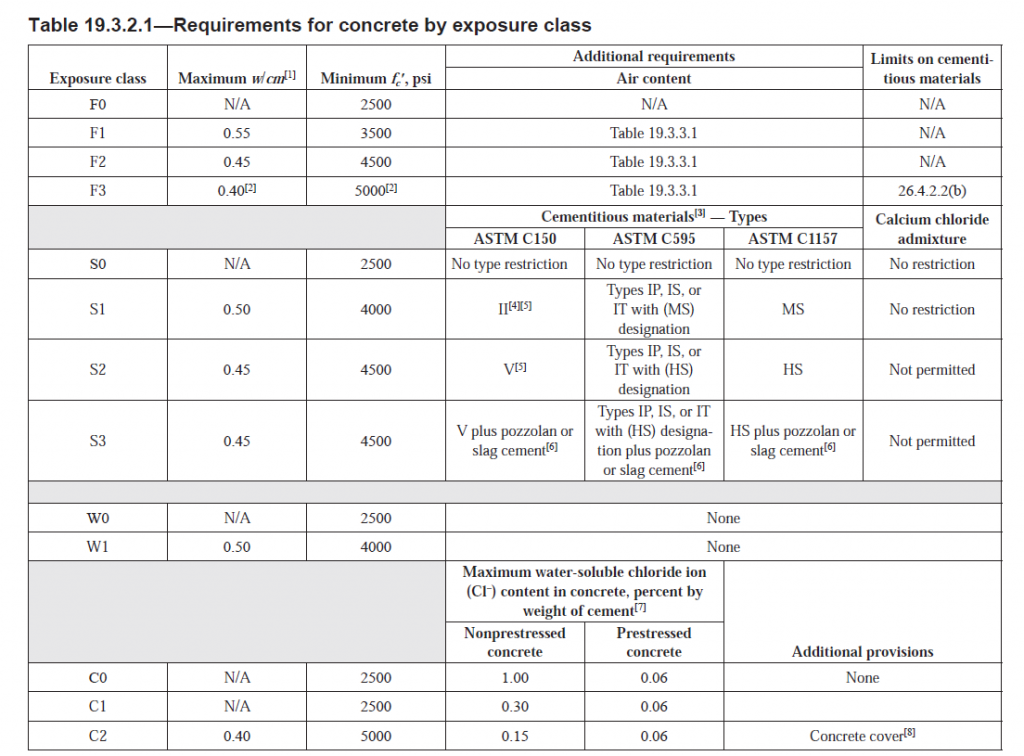

According to the code, the registered design professional (RDP) shall assign exposure classes in accordance with the severity of the anticipated exposure of members for each exposure category in Table 19.3.2.1. This is required for all concrete elements comprising the structure.

Of the four exposure classes of concrete listed in Table 19.3.2.1, the majority of the concrete supplied on commercial project work is one of the F classes. The F denotes “freeze-thaw” and applies to concrete that is exposed to moisture and cycles of freezing and thawing. These cycles can be destructive to concrete because water expands when it freezes.

There are two ways to prevent freeze-thaw deterioration of concrete: 1) keep the water out, or 2) make room within the concrete air-void system for freezing water to expand without damaging the concrete.

Exposure class F0 is sort of an “outlier” in that class F0 is assigned to concrete that will not be exposed to water and cycles of freezing and thawing. Typical examples of class F0 concrete is:

- Concrete elements in climates where freezing will not be encountered

- Concrete elements inside structures that will not be exposed to freezing

- Foundations not exposed to freezing

- Concrete elements, such as foundations, that are buried below the frost line

Based on the exposure classes assigned from Table 19.3.1.1, the concrete mixtures shall conform to the most restrictive requirements therein. Table 19.3.2.1 lists compliance criteria, such as the maximum water-cement ratio, minimum compressive strength, and air content tolerances.

The code requires that the concrete delivered to the project site must comply with the durability requirements of Chapter 19 of ACI 318 (concrete code). This compliance criteria can be found in ACI 318, Sections 19.3.2 and

26.4.3.1. Both IBC Table 1705.3 and IBC Chapter 19, Section 1904 set forth code compliance criteria related to concrete durability. The IBC code and the concrete code (ACI 318) both emphasize the importance of verifying that the proper exposure class of concrete is used for all of the different concrete elements in the structure.

So – how do you confirm (verify) that the appropriate exposure class of concrete is matched up with the proper concrete elements that comprise the project structure?

In IBC Chapter 17, “Special Inspections and Tests,” Table 1705.3, special inspection type #5 requires that the special inspector “verify the use of the required design mix” and also references Chapter 19, “Concrete Design and Durability Requirements” of the concrete code (ACI 318). The special inspection agency, therefore, should receive copies of all approved concrete mix designs for the project. Each approved concrete mix design should be clearly identified as to which exposure class of concrete that it is approved for by the RDP. The project special inspector, according to the IBC code, would be responsible for verifying the delivery of the properly approved concrete mix design by the mix identification number on the concrete delivery ticket. In other words, this very important process should go like this:

- The RDP approves all the proposed concrete mix designs for the project and identifies which concrete exposure classes each mix design is approved for. Each concrete mix design should be identified with a mix ID number. The approved mix design should be forwarded to the special inspection testing agency and all project team members.

- When placing an order to the concrete producer, the contractor should match the mix ID number with the exposure class of concrete that he is ordering.

- The concrete producer should denote the approved concrete mix design ID number on every concrete delivery ticket being delivered to the project.

- The contractor, at the job site, and the concrete special inspector should observe each concrete truck delivery ticket to verify the approved concrete mix design ID number as it relates to concrete exposure class, as well as other code compliance criteria.

As you can see, the process is relatively simple but it is a team effort.

In closing this discussion on CONCRETE EXPOSURE CLASSES, we should all be reminded that whether you are dealing with the IBC code, ACI 318, ACI 301 “Specifications for Structural Concrete,” or ACI 332 which is the “Residential Code Requirements for Structural Concrete,” concrete exposure class code criteria must be complied with. While all of the codes have similar exposure class criteria, there are differences as you move from one to the other.

But Wait — We Have a Lot More to Say!

For a complete picture of the Code and how it relates to Special Inspections, F&R would love to provide a virtual (for the time being) AIA-accredited Lunch & Learn presentation to the professionals at your firm.

Call the Experts at F&R!

Alan S. Tuck

Director of Code Compliance & Training

T 540.344.7939

M 540.798.4440

How does a person know which particular exposure class of concrete to use on each of the different types of concrete elements in the project? The simple answer is for Speaking in Code (SIC) to tell the person to spend some time reading ACI 318, Chapter 19, Section 19.3, “Concrete Durability Requirements.” It’s a big section – about eight pages – and it is loaded with ACI 318 code compliance verbiage about exposure categories and classes of concrete.

How does a person know which particular exposure class of concrete to use on each of the different types of concrete elements in the project? The simple answer is for Speaking in Code (SIC) to tell the person to spend some time reading ACI 318, Chapter 19, Section 19.3, “Concrete Durability Requirements.” It’s a big section – about eight pages – and it is loaded with ACI 318 code compliance verbiage about exposure categories and classes of concrete.