Concrete Masonry Units, Fire Ratings, and Field Verification

The masonry society (TMS) and the TMS 402/602 masonry code only address field verification of the code compliance of concrete masonry units (CMUs) in a general way. It certainly does not specify field special inspections or testing during masonry construction intended to verify the fire rating of the project CMU. So if the project special inspector does not verify that the field CMUs used during construction phases have the proper fire rating as required by the construction documents, who is going to do this? Probably nobody!

This may be a good time to address the IBC code definition of special inspection. The IBC code in Chapter 2 defines special inspection as, “Inspection of construction requiring the expertise of an approved special inspector in order to ensure compliance with this code and the approved construction documents.” Read and understand the IBC special inspection definition carefully. It appears that the IBC code is telling us that the special inspector’s primary responsibility is to ensure compliance with the IBC code, as well as the approved construction documents. Do not forget the “construction documents” part of the IBC definition, since it will become a pertinent part of the balance of this article and discussion.

IBC CODE – CHAPTER 7

Section 722.3.2 Concrete masonry walls. “The fire-resistance rating of walls and partitions constructed of concrete masonry units shall be determined from Table 722.3.2. The rating shall be based on the equivalent thickness (ET) of the masonry and type of aggregate used.”

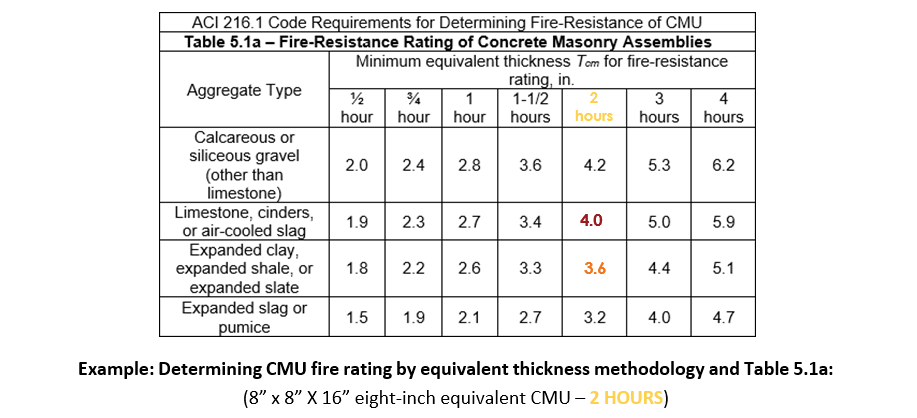

It is important to note that Section 722.3.2 of the IBC code states that the fire-resistance rating of walls constructed of CMUs shall be determined from Table 722.3.2, and the rating shall be based on the equivalent thickness of the masonry used on the project. It should be pointed out that the equivalent thickness values and fire-resistance rating listed in IBC Table 722.3.2 are identical to the values listed in Table 5.1a, “Fire-resistance rating of concrete masonry assemblies,” of ACI/ TMS 216.1, which is entitled “Determining Fire Resistance of Concrete and Masonry Construction Assemblies.” ACI/TMS 216.1 (and Table 5.1a) is adopted by IBC and is listed in Chapter 35 of the IBC code book and is code by reference. It has been accepted practice for years to determine the fire- resistance rating of concrete masonry walls based on the type of aggregate used to manufacture the CMUs and the calculated equivalent thickness of the CMUs.

Attempting to determine the fire rating of those eight-inch equivalent CMUs comprising most of the load- bearing masonry in all those new school projects can create a real conundrum when it comes to verifying the actual fire rating of the field CMUs. The conundrum can be simplified considerably just by implementing Table 5.1a, which is part of the IBC code.

The field CMUs are sampled (6 CMUs) at the hypothetical high school project in accordance with ASTM C90, “Specification for Loadbearing Concrete Masonry Units,” and tested in accordance with ASTM C140, “Sampling and Testing Concrete Masonry Units.” Both ASTM C90 and C140 are adopted by the IBC code and listed in Chapter 35 of the IBC code book.

By utilizing laboratory test results on CMUs that were sampled at the project site, the equivalent thickness (ET) of the 8” x 8” x 16” CMU is found to be 3.82 and the 8-inch CMUs were manufactured by blending 60% expanded shale lightweight aggregate with 40% limestone screenings. Sixty percent of 3.6 (two-hour fire rating column for expanded shale) equals 2.16 ET. Forty percent of 4.0 (two-hour fire rating column for limestone screenings) equals 1.6 ET. The ET of 2.16 is added to the ET of 1.6 for a combined ET of 3.76 ET, which is the minimum ET required for a two-hour fire rated CMU with this blend of aggregates according to ACI/TMS 216 and Table 5.1a. The laboratory-determined ET of 3.82 for these project CMUs is thereby in compliance with Table 5.1a for a two-hour fire rating.

Establishing CMU fire ratings based on laboratory testing in accordance with ASTM C140 has become standard practice. This calculation method is an economical and commonly used method of determining concrete masonry fire-resistance ratings. This calculation method is fully described in ACI/TMS 216.1 and IBC Section 722, and determines fire-resistance based on the equivalent thickness of concrete masonry units and the aggregate types used to manufacture the units.

Okay, let’s do a quick analysis and summation of the snippets of various code information we have covered thus far. The registered design professional (RDP) establishes what fire rating the CMUs on the project should be and stipulates these criteria in the construction documents. As discussed earlier, part of the project special inspector’s duties is verifying compliance with the approved construction documents. At some time during the project construction phases, the fire rating of the CMUs should be verified to ensure compliance with the construction documents. The CMU submittal reflecting compliance with ASTM C90 that was submitted prior to the start of construction phases does not mean that all of the CMUs used during the construction phases comply with ASTM C90. CMU construction progress samples are required.

At the risk of being a little redundant, IBC Chapter 7, Section 722.3.2, states that, “the fire-resistance rating of walls and partitions constructed of concrete masonry units shall be determined from Table 722.3.2. The rating shall be based on the equivalent thickness of the masonry and type of aggregate used.” Most people tend to defer to Table 5.1a of ACI/TMS 216.1 to make the fire rating calculations; however, either Table 5.1a or IBC Table 722.3.2 is acceptable, and both tables are identical and are code by reference.

ASTM C90 and ASTM C140 infer that project CMU samples should be taken during the progress of construction phases. ASTM C 90 used to absolutely specify that CMU project samples be tested to verify compliance with ASTM C90, but that verbiage was deleted from ASTM C90 during a previous code cycle in favor of a more nebulous narrative. Thank you, code gods, for that favor. We all should be reminded from time to time that ASTM C90 and C140 are incorporated into the IBC code and are code by reference.

IBC Chapter 21, “Masonry,” Section 2103.1, also stipulates that the CMUs must comply with Article 2.3 of TMS 602 (masonry code) and Article 2.3 mandates that the CMUs conform to ASTM C90, which is comprised of a host of code-required compliance criteria including dimensions, web thicknesses, face shell thicknesses, density criteria, compressive strength criteria, and even CMU appearance criteria.

The primary point throughout this Speaking In Code article is that the only way to verify that the project masonry complies with the required code compliance criteria is to inspect and test CMU samples during construction phases to verify compliance with the IBC code, the masonry code (TMS 402/602) and, of course, the construction documents.

But Wait — We Have a Lot More to Say!

For a complete picture of the Code and how it relates to Special Inspections, F&R would love to provide a virtual (for the time being) AIA-accredited Lunch & Learn presentation to the professionals at your firm.

Trouble deciphering the Code? Call the experts at F&R!

Alan Tuck, Director of Code Compliance & Training | T 540.344.7939 | M 540.798.4440 | atuck@fandr.com