Concrete special inspections…special indeed, but not simple

Have you ever heard someone say, “Special inspection of concrete is one of the more SIMPLE special inspection processes to teach and learn?” We have, many times, and it is absolutely NOT TRUE. Perhaps the people that say this, think that concrete special inspections consist of only those plastic concrete tests provided by special inspectors at the job site like slump tests, air content tests, unit weight tests, concrete temperature determinations and molding compressive strength specimens. All of these plastic concrete tests are required by the IBC building code but there is much more to concrete special inspections STARTING with IBC Table 1705.3.

The primary special inspection “Bible” is thought, by many, to be Table 1705.3, “Required Special Inspections and Tests of Concrete Construction” and it is found in IBC, Chapter 17. This table lists twelve (12) different line items under a column which specifically describes 12 types of special inspections that must be provided on all projects. Does this mean that there are ONLY 12 basic special inspections to be provided by the concrete special inspector on construction projects? HARDLY.

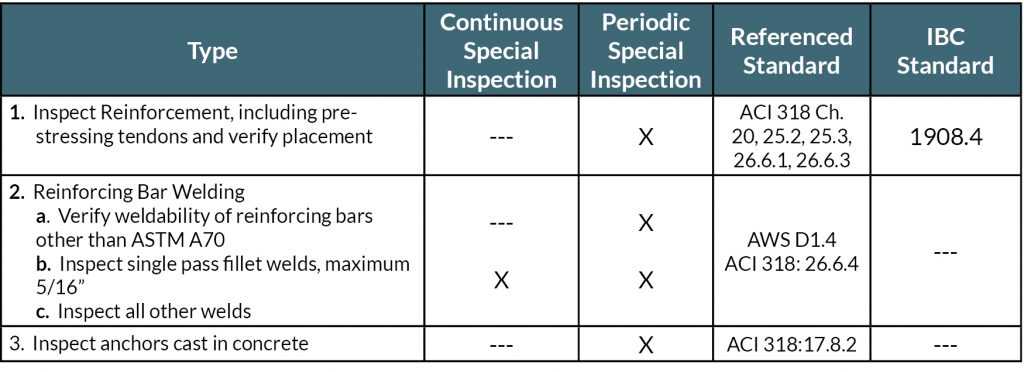

Table 1705.3 – Required Special Inspections and Tests of Concrete Construction

A portion of Table 1705.3 is listed above to assist in explaining the magnitude and complexity of special

inspection and testing services required of the project special inspector by this table. This portion of the table lists only three (3) of the 12 special inspection tasks that are addressed in Table 1705.3. The first column lists the general type of special inspection. The second and third column simply lists whether the inspection is a continuous or periodic special inspection. The fourth column entitled “referenced standard” is the most important column of Table 1705.3 and lists numerous ACI and ASTM standards that describe, in more detail, what special inspections and tests are really required by the IBC code. Lastly, the fifth column is the IBC standard column and any information in this column will reflect criteria from IBC chapter 19, “Concrete.” The provisions set forth in chapter 19 mostly restate the provisions listed in ACI 318; however, some of the provisions of IBC chapter 19 differ from the ACI 318 code and these provisions (that are different from code) usually are listed in italics.

The first type of special inspection listed in Table 1705.3 is related to reinforcing steel and as you track across the table to the items listed under referenced standards, you will see ACI 318, chapter 20, as well as ACI 318 sections 25.2, 25.3 and sections 26.6.1 through 26.6.3 in ACI 318 chapters 25 and 26 respectively. As you review these code sections you will see verbiage related to minimum concrete cover requirements (chapter 20) as well as information and code criteria related to rebar spacing, hooks, stirrups, bend diameters (chapter 25) and information regarding concrete production compliance criteria (ASTM C 94) as well as information about concrete placement and consolidation (chapter 26), curing information and narrative related to the molding of concrete test specimens. The point is that the information listed in the referenced standard column was created to define the special inspections that are listed in a general way in the first column of Table 1705.3 under the heading “type” of inspection.

Within Table 1705.3 and those 12 different line items of types of special inspections, there are more than 50 ACI and ASTM inspections and tests stipulated that range within the jurisdiction of the concrete special inspector. In order to study these tests and inspections, review the ACI and ASTM standards listed under the referenced standard column of Table 1705.3. Most of these ACI and ASTM designations are listed in IBC, Chapter 35 which makes them enforceable as part of the CONCRETE CODE; standards like ASTM C 29, C31, C33, C39, C94, C140, C172, C173, C231, C1064, etc. Any experienced concrete special inspections project engineer or engineering technician will recognize the name (title) of these standards without the ASTM companion “title” (which is not listed in this paragraph) because they implement these code mandated test methods and inspections almost every day. If that last statement did not IMPRESS those of you who do not provide concrete special inspections regularly, then consider the fact that each of those 10 ASTM designations listed (above) in this paragraph sets forth an additional 4 to 6 tests or inspections per reference standard for the special inspector to do. Simple multiplication yields over 50 code required inspections and tests by the 10 aforementioned ASTM standards?

Sometimes when you catch your inspector staring hopelessly at plans or blankly out into the distance it might mean that he/she is trying to keep it all straight – and there is SO MUCH to keep straight. We will not devote the time to break down every single reference standard mentioned in the “referenced standard” column for all of the special inspection tasks listed in column one of Table 1705.3 as we just did for the first inspection task (reinforcing steel); however, we will list, herewith, most of the special inspections and tests invoked by the numerous referenced standards listed in Table 1705.3 for special inspection tasks number two through inspection task number 12. Some of them (but not all) are listed as follows:

- Determining that individuals welding rebar are certified welders according to AWS D1.4

- Verify that reinforcing steel is welded in accordance with requirements of AW D1.4

- Verify that welding requirements for A706 and A615 rebar are complied with

- Verify that reinforcing steel cross bars are not welded (unless permitted by SER)

- Verify that reinforcing steel spacing and installation complies with contract documents

- Be present during the placement of anchor rods

- Report diameter, grade, type and length of anchor rod or embedded item

- Extent or depth of embedment

- Continuous presence during placement of adhesive anchors (installed horizontally or upwardly)

- Verify that materials used and installation procedures comply with approved construction documents and manufacturer’s printed installation instructions (MPII)

- Verify that adhesive anchors comply with ACI 355.4, section 13, special inspections

- Verify that anchor installer is a certified installer according to ACI

- Verify that concrete mix is approved and complies with ACI 301, article 3.2.3

- Verify that concrete mix has designated exposure class according to ACI chapter 19

- Verify that concrete mix design and proportions comply with contract documents

- Test plastic concrete to verify compliance with contract documents and ACI 318

- Mold compressive strength specimens according to ACI 318 and IBC Table 1705.3

- Provide initial curing for concrete test specimens according to ASTM C 31 and Table 1705.3

- Verify mixing and unloading of ready-mix concrete according to ASTM C 94 and code

- Observe any addition of concrete mix water at job site is according to ASTM C 94 and code

- Observe concrete placement according to ACI 318, section 26.5 including monitoring hot weather and cold weather concrete placement procedures

- Observe concrete mixing drum revolutions comply with code according to ASTM C 94

- Observe concrete mixing time parameters according to contract documents and ACI 301

- Observe concrete temperatures and ambient air temperatures according to contract documents and ACI 301

- Document visual weld inspection on any concrete embeds according to AISC 360

- Observe that appropriate curing of new concrete construction complies with contract documents and ACI 301

- Verify that concrete forms comply dimensionally with contract documents

- Observe that finishing operations and concrete curing procedures comply with contract documents and applicable ACI and ASTM reference standards

- Verify that footing bottom elevations and other concrete subgrades comply with contract documents, IBC Table 1705.6 and approved geotechnical report

- Observe construction joints, isolation joints, etc. for compliance with contract documents

There are many more additional reference standards and reference codes listed in Chapter 35 of the IBC code book and ACI 318 code that stipulate even more code required tests and inspections on concrete. The special inspection tasks and tests listed in this article are derived almost entirely from IBC, chapter 17, Table 1705.3 and the numerous referenced standards and codes that are included within Table 1705.3. Additional concrete special inspections and tests are stipulated ACI 355.4, AISC 360, AWS D1.1, AWS D1.4, ACI 301 and numerous other ASTM standards not mentioned in this particular article. I think that it is fair to say that most people in the construction industry regardless of their trade (architects, engineers, contractors, building officials, concrete ready-mix producers, etc.) do not fully understand the vast array of inspections, tests and observations required of the concrete special inspector to employ daily as he or she observes construction procedures and construction materials at the project construction site. I think that the main point to convey is what we said in the very beginning of this article:

“Concrete Special Inspections may be special but they are certainly not SIMPLE.”

But Wait, We Have a Lot More to Say!

CODE issues got you cracking up? For a complete picture of the Code and how it relates to Special Inspections, F&R would love to provide an AIA accredited Lunch & Learn presentation to the professionals at your firm. A catalog of available presentations can be downloaded here. Contact Alan Tuck for more details at: atuck@fandr.com