aisi S240 code

…and cold-formed steel light-frame construction

Just when you thought we couldn’t make things more complicated. Here we go.

The 2015 editions of the American Iron and Steel Institute (AISI) standards for cold-formed steel including AISI S240, AISI S400 and AISI S202 have been referenced in the 2018 edition of the International Building Code (IBC).

AISI S240, North American Standard for Cold-Formed Steel Structural Framing

AISI S400, North American Standard – Seismic Design of Cold-Formed Steel Structural Systems

AISI S202, Code of Standard Practice for Cold-Formed Steel Structural Framing

The comprehensive standard of AISI 240 was formed by merging AISI standards S200, S210, S211, S212, S213 and S214. AISI 240-15 supersedes all previous editions of these individual standards. Additionally, AISI 240-15 builds upon this foundation by adding the first comprehensive chapter (Chapter D) on quality control and quality assurance (special inspections) for cold-formed steel-light frame construction. This new AISI S240 should be reviewed in tandem with the new IBC 2018 Section 2211, “Cold-Formed Steel Light-Frame Construction” which has been modified when compared to previous IBC Section 2211 editions.

This Speaking in Code (SIC) article summarizes almost all of the modifications of IBC 2018, Section 2211 and then offers some remarks and conclusions on AISI S240, especially Chapter D of AISI S240 which is all about quality control and quality assurance (special inspections).

IBC 2018 CODE: Section 2211.1 General Structural Framing. For cold-formed steel light frame construction, the design and installation of the following structural framing systems, including their members and connections shall be in accordance with AISI S240-15, and Sections 2211.1.1 through 2211.1.3 of IBC as applicable:

- Floor and roof systems

- Structural walls

- Shear walls, strap-braced walls and diaphragms to resist in-plane lateral loads

- Trusses

2211.1.1 Seismic requirements for cold-formed steel structural systems. The design of cold-formed steel light frame construction to resist seismic forces shall be in accordance with the provisions of Section 2211.1.1.1 or 2211.1.1.2 as applicable.

2211.1.1.1 Seismic Design Categories B and C. Where a response modification coefficient, R, in accordance with ASCE 7, Table 12.2-1 is used for the design of cold-formed steel light frame construction assigned to Seismic Design Category B or C, the seismic force-resisting system shall be designed and detailed in accordance with the requirements of AISI S400.

Exception: The response modification coefficient, R, designated for “Steel systems not specifically detailed for seismic resistance, excluding cantilever column systems” in ASCE 7 Table 12.2-1 shall be permitted for systems designed and detailed in accordance with AISI S240 and need not be designed and detailed in accordance with AISI S400.

2211.1.1.2 Seismic Design Categories D through E. In cold-formed steel light frame construction assigned to Seismic Design Category D, E or F, the seismic-force resisting system shall be designed and detailed in accordance with AISI S400.

2211.1.2 Prescriptive Framing. Detached one and two-family dwellings and townhouses, less than or equal to three stories above grade plane, shall be permitted to be constructed in accordance with AISI S230 subject to the limitations therein.

2211.1.3 Truss Design. Cold-formed steel trusses shall comply with the additional provisions of Sections 2211.1.3.1 through 2211.1.3.3.

Truss design drawings. The truss design drawings shall conform to the requirements of Section I1 of AISI S202 and shall be provided with the shipment of trusses delivered to the job site. The truss design drawings shall include the details of permanent individual truss member restraint/bracing in accordance with Section I1.6 of AISI S202 where these methods are utilized to provide restraint bracing.

2211.1.3.2 Trusses spanning 60 feet or greater. The owner or owner’s authorized agent shall contract with a registered design professional for the design of the temporary installation restraint/bracing and the permanent individual truss member restraint/bracing for trusses with clear spans 60 feet or greater. Special inspection of trusses over 60 feet in length shall be in accordance with IBC section 1705.2.

2211.1.3.3 Truss quality assurance. Trusses not part of a manufacturing process that provides requirements for quality control done under the supervision of a third-party quality control agency in accordance with AISI S240 Chapter D shall be fabricated in compliance with IBC sections 1704.2.5 and 1705.2 as applicable.

2211.2 Nonstructural Members. For cold-formed steel light-frame construction, the design and installation of nonstructural members and connections shall be in accordance with AISI S220.

AISI S240-15, Chapter D, “Quality Control and Quality Assurance”

AISI S240 Chapter D establishes the minimum QC and QA requirements for material control and installation for cold-formed steel light-frame construction. Minimum observation and inspection tasks deemed necessary to ensure quality construction are spelled out within the new AISI S240 code and especially in chapter D of AISC 240.

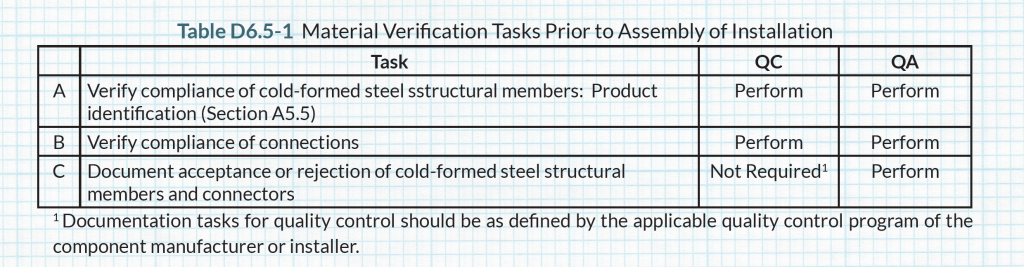

Similar to the AISC 360 code and SDI QC/QA code (2011 edition), AISI S240 Chapter D provides easy to use tables that itemize specific QC and QA inspection tasks to be performed related to such activities as: material verification prior to and after assembly and installation; welding; mechanical fastening; and special provisions for lateral force resisting systems. As an example of the tables set forth in AISI S240, review Table D6.5-1 below:

Detailed inspection tasks to be provided prior to, during and after welding are set forth in tabular formats as well as required inspections after installation of cold-formed steel light frame construction.

Within the AISI S240 Chapter D tables, QC and QA tasks are prescribed as “observe”, “perform”, or “not required”. While different from the IBC Chapter 17 requirements for special inspection, this approach is similar to the AISC 360 code and the SDI QC/QA code requirements. Observe means that items are to be inspected on an intermittent basis, and operations that do not interfere with the ability to perform inspection of these items need not be delayed pending these inspections. The frequency of observations must be adequate to confirm that the work has been performed in accordance with the approved construction documents. On the other hand, perform indicates critical tasks that are to be executed prior to final acceptance for EACH item or element. For the listed tasks, the inspector is required to prepare reports or other written documentation indicating whether the work has been performed in accordance with the approved construction documents.

Quality Control (QC): Controls and inspections implemented by the component manufacturer or installer to confirm that the material provided and work performed meet the requirements of the approved construction documents and referenced standards.

Quality Assurance (QA): Monitoring and inspection tasks performed by a registered design professional, firm or approved agency other than the component manufacturer or installer to ensure that the material provided and work performed by the component manufacturer and installer meet the requirements of the approved construction documents and referenced standards and codes. QA includes those tasks designated “special inspection” by the applicable building code.

Quality control is the responsibility of each contractor, subcontractor and installer on the project for their respective scope of work. Depending on requirements specified by the local jurisdiction, the model building code, or the contract between the contractor and the owner or registered design professionals, the general contractor may also be responsible for hiring the QA inspector for the project at times.

Chapter D does not apply to nonstructural members. Chapter D also does not apply to the manufacture of cold-formed steel structural members, connectors or hold-downs other than material control. Sections D6.5 through D6.9 list the code required inspection tasks of quality control and quality assurance if the inspections performed identify nonconforming material or workmanship. The need for additional inspections AND the rejection of material should be done in accordance with section D7 of the AISI S240 code.

The AISI S240 code includes a complete 70+ page COMMENTARY which starts on page 130 of the S240 document. A thorough review of this COMMENTARY is recommended because it generally points out and clarifies many items that may be missed or misunderstood during a cursory review of the code itself.

Coordinated inspection tasks between quality control and quality assurance is allowed by the AISI S240 code for component manufacturers in remote locations. Approval of the Authority Having Jurisdiction (AHJ) and the Registered Design Professional (RDP) is required in order for quality assurance to rely on quality control. (Section D6.3)

Lastly, model building codes such as IBC often make specific statements about performing inspections to “approved construction documents”. AISI 202 requires the transfer of information from contract documents into accurate and complete shop drawings and installation drawings. Because of this provision, quality control and quality assurance inspection may be performed using shop drawings and installation drawings, NOT original plans and specifications.

But Wait, We Have a Lot More to Say!

CODE issues got you cracking up? For a complete picture of the Code and how it relates to Special Inspections, F&R would love to provide an AIA accredited Lunch & Learn presentation to the professionals at your firm. A catalog of available presentations can be downloaded here. Contact Alan Tuck for more details at: atuck@fandr.com